Our History

Fratelli Pacifici S.p.A. was founded in 1938 when brothers Cesare and Lorenzo decided to combine their vision and skills into an industrial project for the extraction and transformation of Roman Travertine.

After opening several quarries in the area of Tivoli Terme, the company steadily expanded in the national market through the acquisition of laboratories for stone processing and advanced machinery.

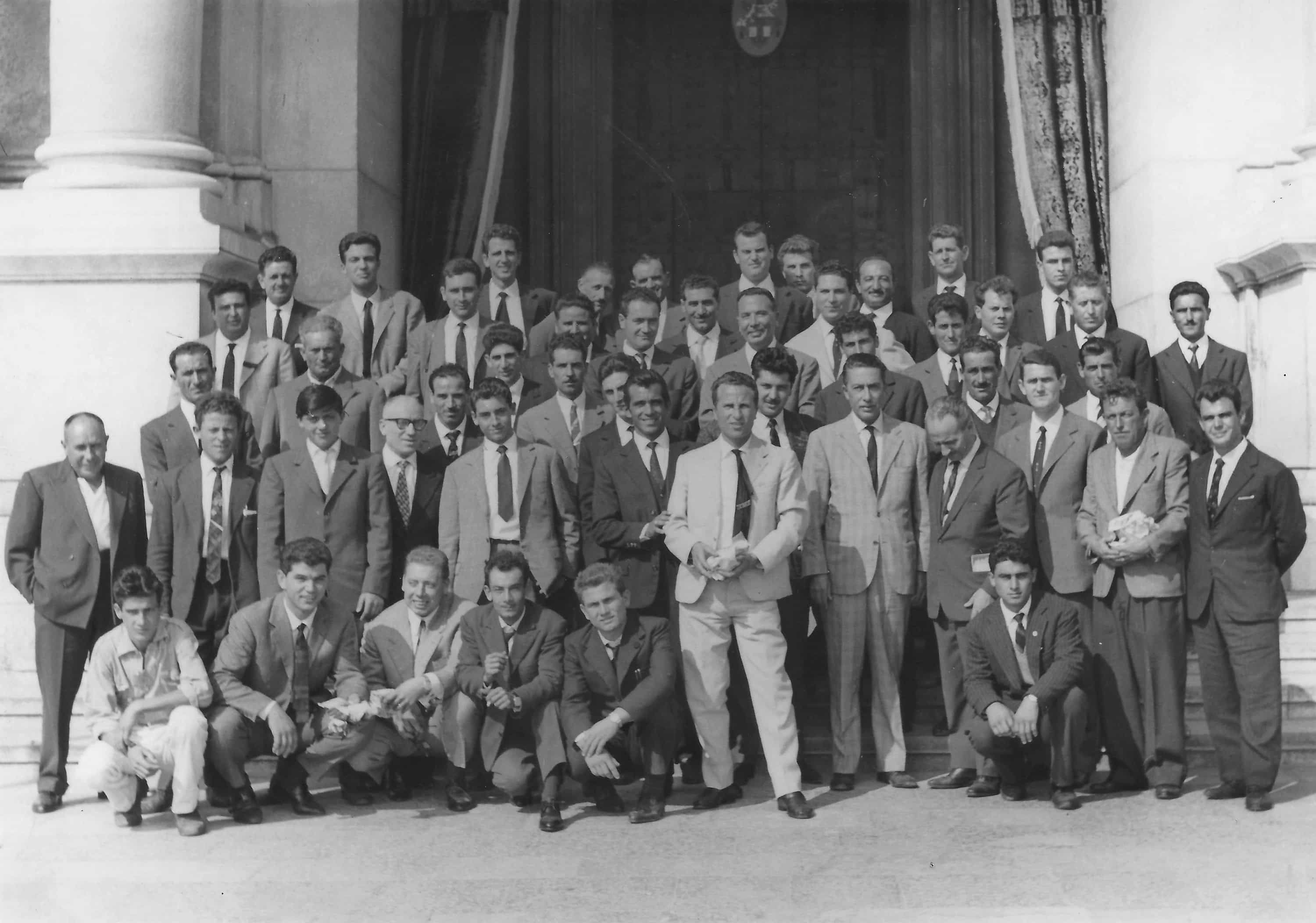

From the forties to the sixties, the company developed and reached a workforce of 150 workers including quarrymen, craftsmen and stonemasons, responding to the growing demand of the Italian market that came with the roaring years of an economic boom. Thus began a tradition based on quality and professionalism, which still distinguish us and make sure that our customers remain satisfied and loyal through time (sometimes for over fifty years!).

Between the seventies and the nineties, the company expanded in Europe and in the global market under the guidance of the second generation, Alessandro and Tommaso Pacifici. Our Roman Travertine was exported to every corner of the world and Pacifici became a benchmark of the industry, setting the highest standards for the quality of the product and its processing.

About Us

Led by the third generation – Francesco and Alessandro Dandini de Sylva and Marco and Francesco Pacifici – the company has started collaborations with renowned architectural and design firms such as Arup Associates, Bennetts Associates, David Chipperfield Architects, Foster + Partners, Henry J Lyons, Maki and Associates, OMA, Pickard Chilton, Renzo Piano Building Workshop and many others.

Today, as the only company working exclusively Roman Travertine, the Pacifici is a leader in the market of blocks, slabs and finished products, boasting 50,000 m³ per year of quarried travertine. The state of the art processing machines allow us to saw up to 4,000 m² per day and produce up to 40,000 m² of finished travertine per month. A team of craftsmen and connoisseurs of all the secrets of the stone are able to execute any kind of work. This is why we are proud to meet the evermore-customized demand for blocks, slabs and finished products the worldwide market constantly requires.

The Quarries

The Pacifici’s quarries are located in the area of excellence for the extraction of Roman Travertine.

The company’s quarries are situated in the area of Tivoli and Guidonia Montecelio, circa 25 km to the east of Rome, in the plains surrounding the Acque Albule’s springs, an optimal zone for the formation and extraction of precious, durable and unique travertine.

Travertine derives its name from the former town, known as Tibur in ancient Roman times; the ancient name for the stone was Lapis Tiburtinus, meaning Tibur Stone, which was gradually corrupted to Travertino (travertine). Its deposit formed during late Pleistocene time over an active strike-slip fault nearby the Colli Albani quiescent volcano.

This stone began to be quarried by the ancient Romans approximately 2,500 years ago and nowday it is still widely appreciated and used by architects and designers all over the world. This happened thanks to the vastness of its extraction basin (about 20 km2 wide and 60 m thick on average) and due to the travertine’s indisputable qualities such as its endurance, its warm and timeless color, its uniformity and its adaptability to various architectural styles. The magical city of Rome embodies all of these styles, from Romanic to Renaissance, from Baroque to Rationalist, from Modernist to Minimalist.

Our Services

We supply Roman Travertine blocks, slabs and finished products.

Throughout the whole extraction and finishing process, intergenerational knowledge, manual dexterity and technology are combined to perform sophisticated and accurate work.

The quarrying activities take place on a daily basis beginning from the so-called “bancata”. The rock is extract stepwise from the quarry by first drilling a series of vertical holes and then cutting vertically large portions of quarry wall using diamond gang saw blade and wire. After cutting through, these towering monoliths are supported only by their base and are detached by pushing them over with the aid of inflatable pillows so they fall on their side. Massive travertine walls are brought to light, from which the finest materials are carefully selected according to color and structure.

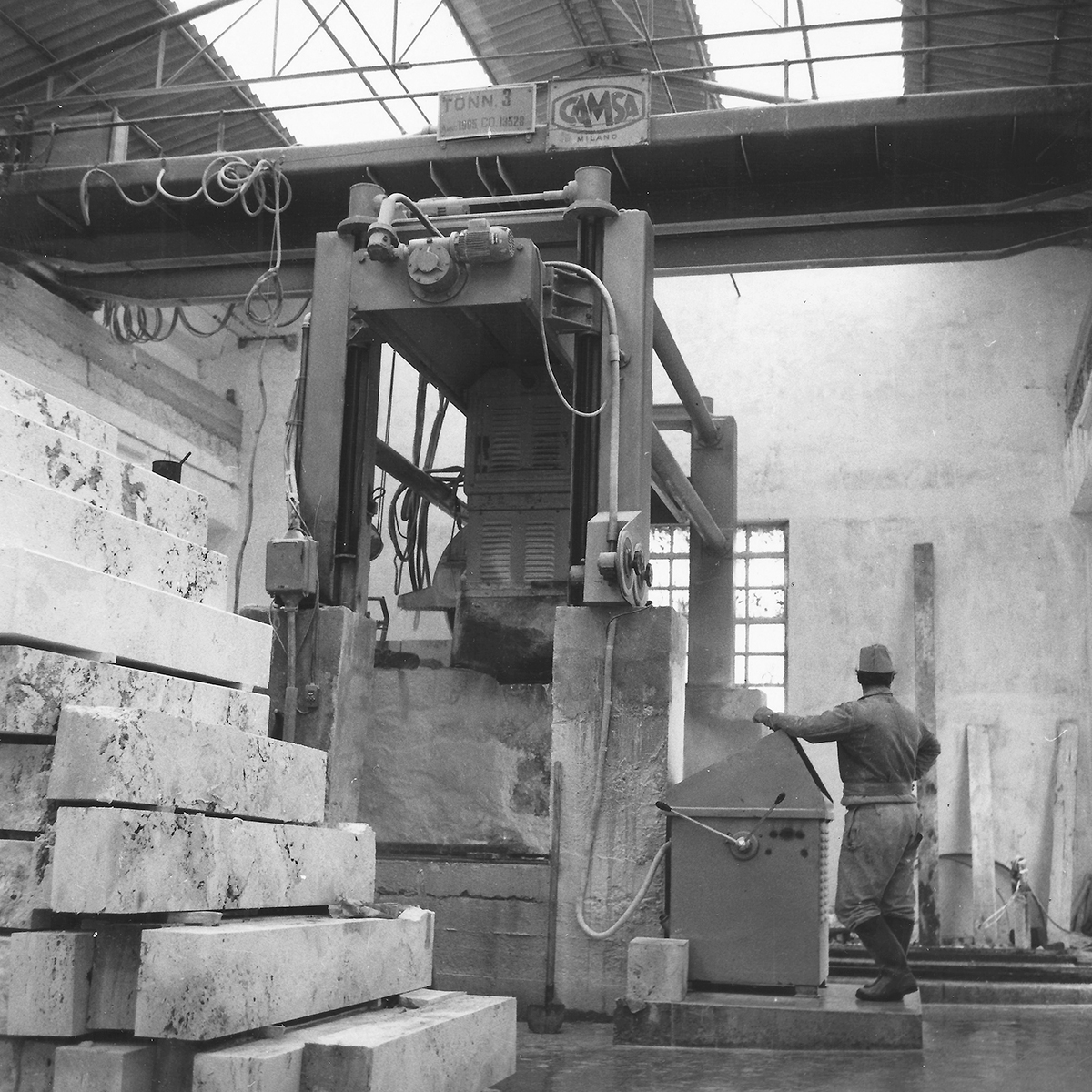

The “bancata” is divided into blocks that are subjected to meticulous production processes using advanced tools and machineries under the careful supervision of qualified technicians. The blocks are then sliced into thin slabs of different thicknesses using gang saws with diamond blades that enable fast, high-precision work. This is followed by the final phase in the laboratory, where the most modern tools are used to apply different finishing to the stone.

The Pacifici company carries out all the phases of extraction and processing of Roman Travertine.